Re:Build develops and manufactures technologically advanced products from concept through production at scale here in the United States using a Brain to Box™ process.

Specialized engineering firms often lack a manufacturing footprint, supply chain capabilities, or commercialization experience. ODMs and traditional CMs lack the front-end ability to translate market data into meaningful product concepts. Further, without scale or long-term manufacturing commitments, they are unwilling to dedicate the vital engineering capabilities (hardware, software, and process) necessary to solve challenging problems and develop technologies. Re:Build has overcome those obstacles by integrating compatible organizations, helping them thrive, and enabling customers to take their idea from inception to commercial production efficiently and effectively.

Re:Build’s Brain to Box approach has six phases. Customers either participate in all six or a plan is tailored to meet their needs.

Projects are launched after consensus on objectives, strategies, and a detailed road map for the commercialization of products, services, and technologies.

Ideas and insights are promptly translated into a mock-up. Detailed development requirements mitigate risk in engineering and prototyping.

Re:Build’s iterative process in engineering and design for manufacturing, which is fundamental to our lean methodology. Products are cost-effective and perform as intended.

The appropriate materials, process, and manufacturing operations are developed so you can focus on your customers and scale. Customers are confident the right product is built correctly.

High-quality final products meet the necessary requirements for safety, reliability, and ease of use.

After a new product is brought to life, smooth delivery is facilitated by skillful supply chain management, assembly, warehousing, and distribution capabilities.

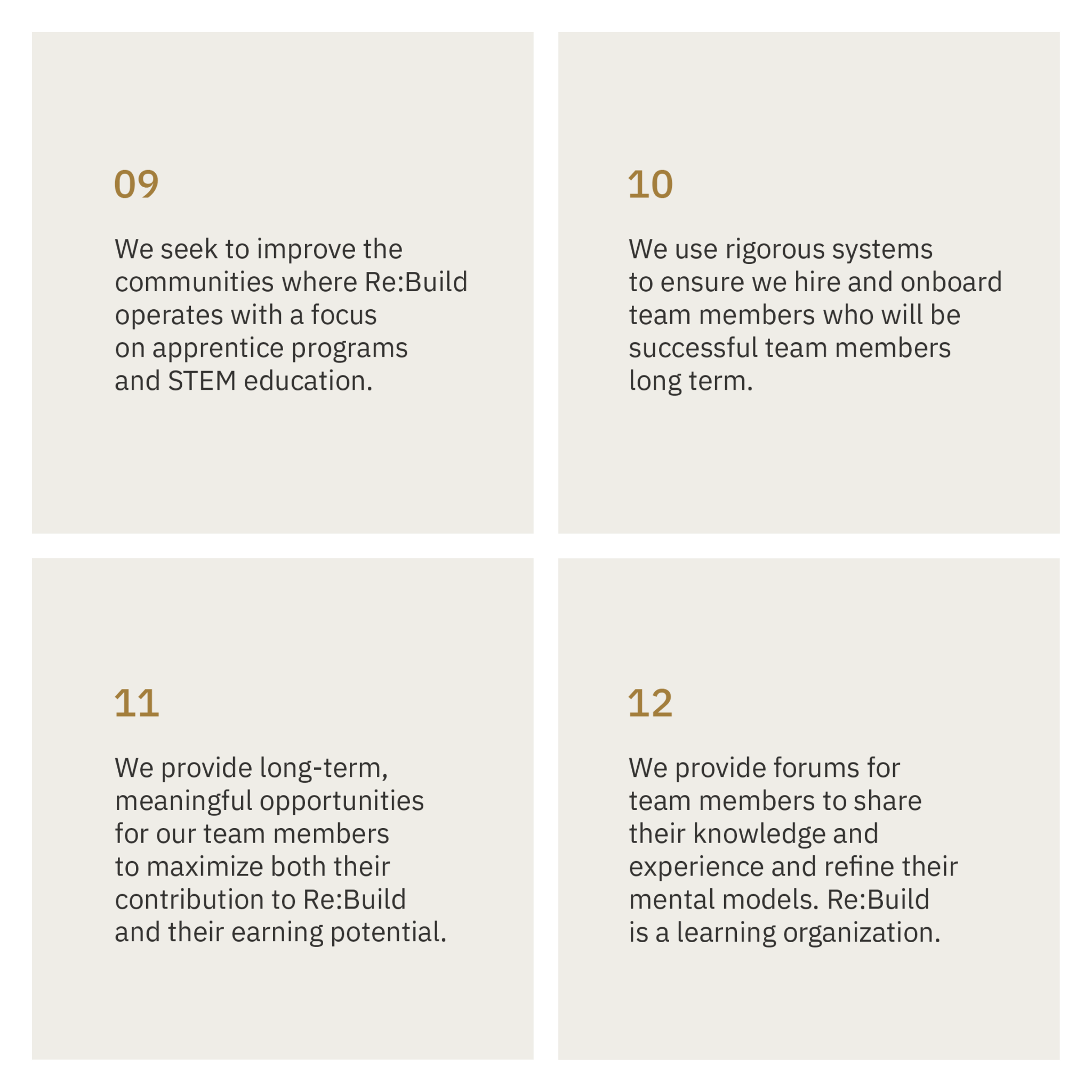

We provide forums for team members to share their knowledge and experience and refine their mental models. Re:Build is a learning organization.

Below is the list of our family of businesses. Within them, you’ll discover the vast spectrum of our capabilities. We are continuing to grow, and new names will be added as acquisitions are finalized. Please click on the logos to learn more.

Re:Build Manufacturing’s leadership is united in its purpose: build a better future over the long term for the company’s customers, employees, partners, communities, and shareholders through a new model of industrialization. The management team has an extraordinary depth and breadth of experience and hails from a variety of backgrounds.

Re:Build identifies highly capable U.S. engineering and manufacturing businesses that operate in the industries we serve and have the potential to achieve greater success through an acquisition by us. Those businesses need to demonstrate a strong desire to be a part of Re:Build’s unique ecosystem of companies with complementary capabilities. We also look for them to be aligned with our goals and be committed to working in a mutually beneficial way on behalf of our customers, employees, and local communities.

Re:Build’s goal is to help revitalize the U.S. manufacturing base over the coming decades, creating substantial opportunities for our employees and the communities where we operate. We aim to do that by building America’s next great industrial company—growing a family of businesses that combine cutting-edge enabling technologies and operational superiority in aerospace and defense, cleantech, health, industrial equipment, and mobility. Our expertise is in product innovation, advanced components, systems production, and industrial automation.

If you think your engineering or manufacturing company could benefit from our expertise, are interested in becoming a Re:Build company, or simply want to know more about our organization, please reach out.