Re:Build’s engineers are experts in manufacturing optimization. We develop customized automation solutions, from a semiautomated work cell to a fully-automated factory line, that improve production efficiencies and reduce costs. Automation enables you to remove simpler tasks from the workflow and ensures your skilled-labor employees have a greater impact on production by adding more value to the product.

Every automation project is unique. Re:Build analyzes the risk and economic impact of your challenges and then provides the optimal engineering solution to help you successfully meet your goals. We understand the challenges of low-rate production and constraints on capital and work closely with you and your teams to build a production roadmap that meets your immediate needs as well as positions you for growth.

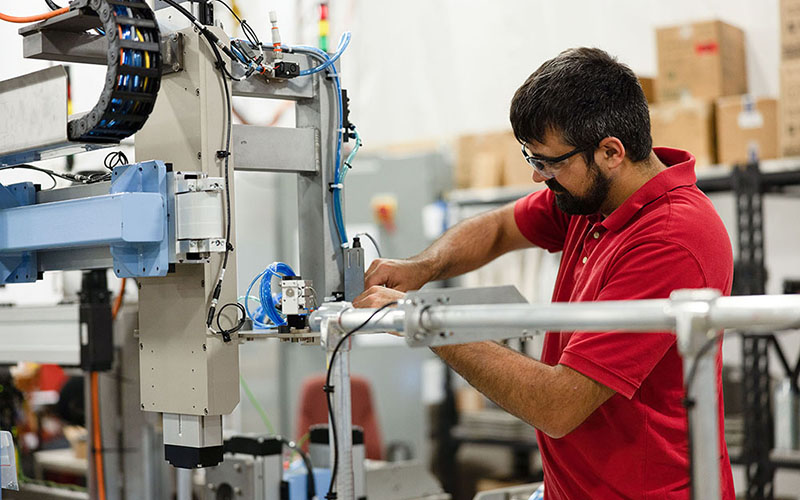

Our engineers and technicians can build complex automation systems and develop rigorous testing criteria that will satisfy the demands of your industry. We provide custom machine design and build, installation, systems controls and integration, and the ongoing maintenance and troubleshooting support needed to keep your system running effectively throughout its useful life.

Automation programs begin with prototype development and necessary adjustments are made promptly. This discovery phase enables us to identify and mitigate potential risks.

Re:Build upholds lean manufacturing principles and understands that continuous improvement is critical to success in the market. We are committed to incorporating innovative design changes and suggesting ways to reduce costs or improve efficiency throughout the life of your program.

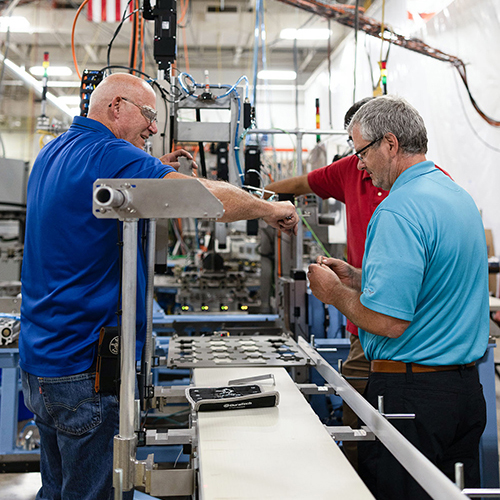

Re:Build provides automation systems integration services in process and manufacturing industries. Our experienced control system integrators are adept at taking early-phase engineering input and general requirements and collaborating with your team to generate final-product engineering documentation, specify and build custom software, and ensure installation and test qualifications are executed to the highest satisfaction.

Re:Build has the operational excellence and engineering skills to create enhanced or new processes. Our team’s consultative approach to process discovery enables us to identify opportunities to improve efficiencies. We conduct throughput analysis and human-factors assessments and make recommendations for automation solutions that will improve workflow output, quality, and safety.

A well-functioning line is optimized for profit. Our team assesses machinery lines, identifies the cause of common defects, and recommends improvements. Re:Build’s lean coaches provide guidance and insight to cross-functional teams as they conduct Rapid Improvement Events and Kaizen for tactical problem-solving.

Re:Build provides high-speed data acquisition systems to measure product properties and machine characteristics in real time. These systems can verify production results and characterize machine performance for continuous improvement. Knowledge of modern techniques such as Model Free Adaptive Controllers (MFA), S95 / S88 batch management, and OEE (Overall Equipment Effectiveness) ensures clients’ equipment operates at peak performance.

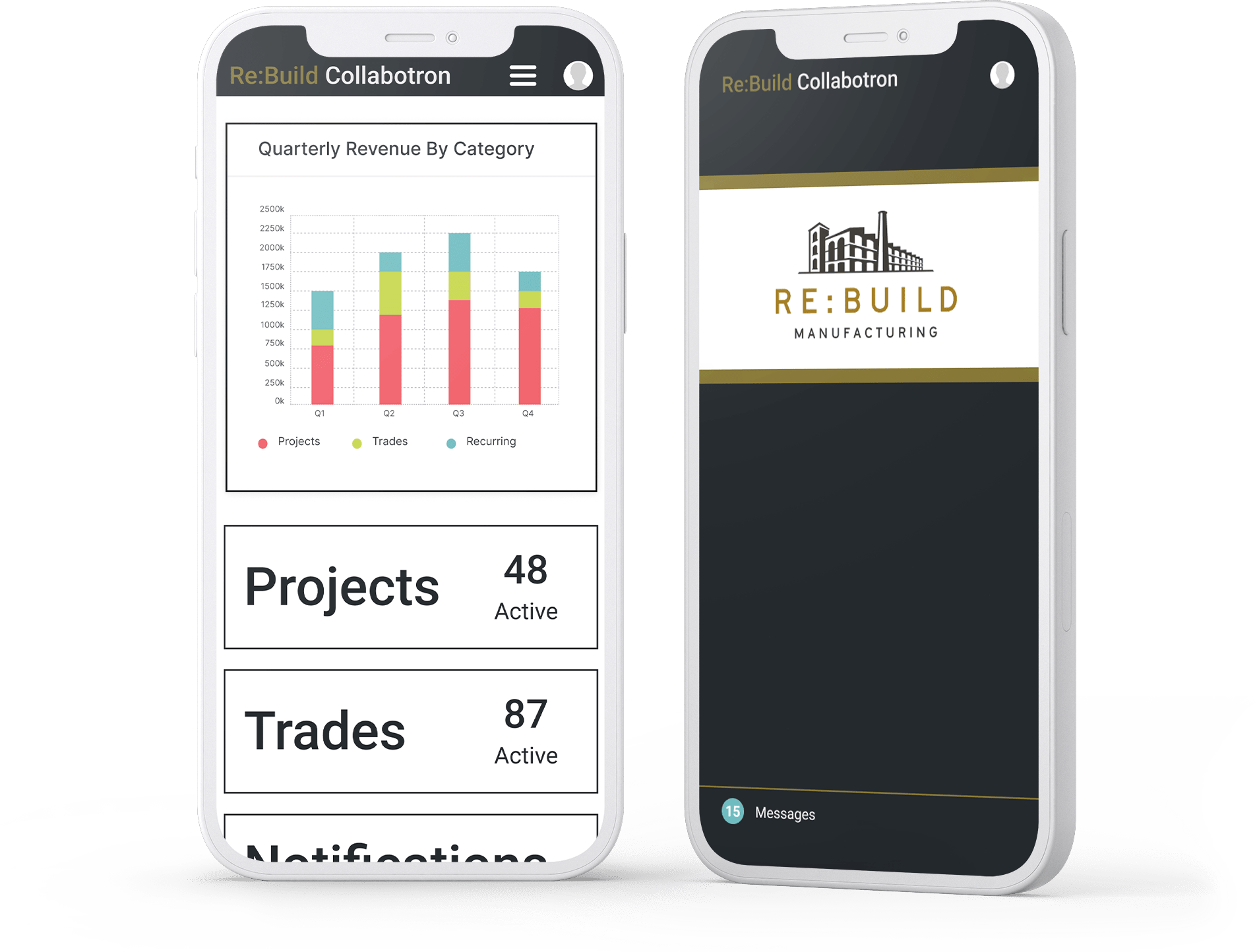

Staying competitive requires intelligent products and equipment. Re:Build connects physical products and equipment to digital applications and services for smarter solutions. We improve system performance and cost of ownership through advanced sensor integration, edge computing, and database connectivity.

System topologies, custom-engineered APIs and databases, predictive analytics, usable interfaces, and tailored data visualizations.

Embedded web- and mobile-software engineering, including APIs and operational support.

Custom algorithm development, data query, monitoring, and computer vision.

Our strategic partnership extends beyond machine installation. We stand behind our automation solution and keep it running effectively throughout its useful life.

The Re:Build team provides continuity throughout specification, design, integration, development, implementation, calibration, troubleshooting, start-up, debugging, and production. After installation, we offer an evaluation of your equipment and process, including cycle times. These audits come with recommendations for maintenance, repairs, capacity expansions, refurbishments, and more.

Re:Build has experience incorporating cleaning technologies and in-process treatments into the machine design. Our experts understand the systems and controls needed to provide an effective cleaning functionality to your equipment.

Re:Build is an expert in the development of complex manufacturing processes and knowledgeable about the testing those processes require. Whatever your industry and the regulations that guide it, we’ll work with you to guarantee that your process meets specifications.

The customer owns an egg farm and sells to a supermarket chain that expects vendors to deliver superior quality food. The farm owner requires its nearly one million chickens have fresh air, clean water, and abundant feed and roam in an environment that has controlled lighting and temperature and overall cleanliness. Re:Build Optimation was tasked with developing and integrating automation so that the eggs would never be touched by humans. We developed a robust, completely automated solution that includes a control system, I/O wiring, and web-enabled HMI. The eggs are untouched, safe, and valued by the farm’s customer. Re:Build remains engaged with the farm and provides a program of continual improvements.

Let’s talk about your unique challenges and how Re:Build can help you.