Member company feature

Accelerating Technology to Product Commercialization

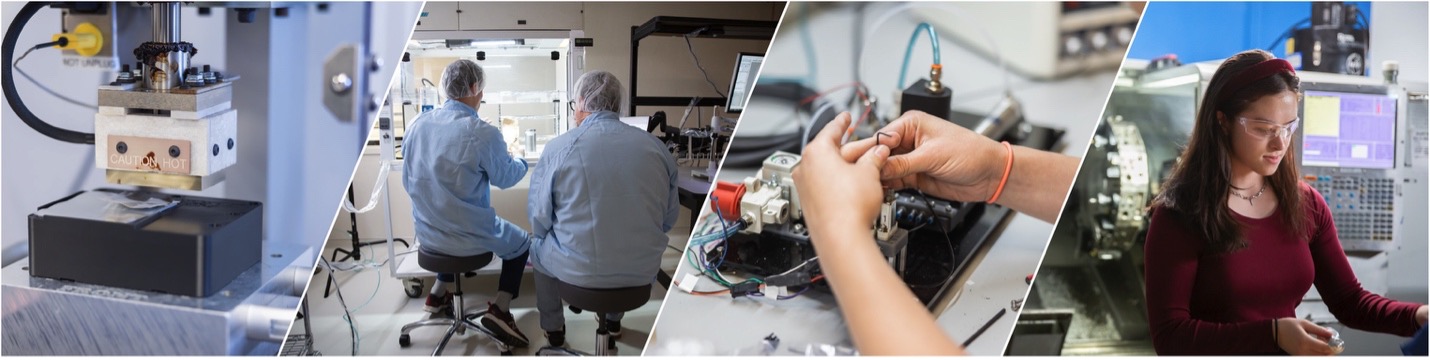

At Re:Build Fikst, we collaborate with clients to transform their technology into a tangible, market-ready product. Whether you need full-scale engineering development, targeted support for a short-term experiment, or a quick, practical solution to a complex technical problem, we’re here to help you.

Engineering That Thrives in the Unknown

We excel in environments of ambiguity, forging new paths where traditional approaches fall short. Our engineers apply first principles thinking and creative problem-solving to engineer solutions from the ground up. This approach allows us to tackle the most challenging technical hurdles, bridging the crucial gap between scientific innovation and commercial viability.

Integrated Expertise Across Disciplines

Our team functions as a true extension of your R&D capabilities, bringing together mechanical, embedded systems, thermal, and fluidic expertise under one roof. This integrated approach eliminates the communication barriers and handoff delays that typically slow development, accelerating your path to market through seamless collaboration across disciplines.

From Concept Development to Low-Volume Production

Industry Expertise That Makes a Difference

Learn More

Re:Build Fikst recently refreshed our website to better showcase our history, expertise, and dedication to our clients. To learn more about our capabilities, culture, history, and industry expertise, check it out at the link below.

Tom Merle

General Manager

tmerle@fikst.com