The Simplest Way to Modernize Wire Harness Manufacturing

Every so often, a product arrives that feels so natural and immediately useful that you wonder how the industry ever worked without it. For wire harness manufacturing, smartBuild is that kind of breakthrough, replacing the complexity and tedium of classical assembly techniques with a guided, intelligent, and effortless experience that dramatically reduces errors, accelerates production, and brings clarity to even the most complicated builds.

Re:Build Cadonix has spent years of research and testing in real factory environments to refine smartBuild. Instructions are clear, each visual is natural, and steps flow in a way that mirrors how technicians think. The more you use it, the more evident it becomes that this is the digital future the wire harness industry has been waiting for.

Proven in production, smartBuild provides 100 percent traceability, accelerates production by cutting assembly time up to 40 percent and “design to build time” by 95 percent, adding over four percent profit margin to every harness built.

SmartBuild begins with clarity, replacing cluttered drawings and scattered instructions with guided, animated steps that show technicians exactly what to do, from routing wires and terminating connectors, to placing labels and applying braiding. Wires highlight in the right colors (including secondary and tertiary stripes), cavities illuminate for precise wire placement, and wire variations like twisted-pair cables are given clear visual cues.

Each instruction and animation is automatically generated directly from wire harness engineering data, meaning the build sequence stays accurate as the design evolves. Direct integration with Cadonix Arcadia, the industry’s leading intelligent component database, means there’s no extra work re-creating component models – the digital thread continues seamlessly from design to production.

Industry-leading manufacturing teams report that new technicians become productive in a fraction of the time. What used to take weeks to train new workers on drawing interpretation and wire harness assembly, now takes less than half a day. Before, only the most experienced builders could assemble complex harnesses. Now, smartBuild opens the door to newer operators manufacturing complex harnesses. SmartBuild doesn’t just make manufacturing easier, it makes success and productivity more accessible.

SmartBuild is designed to adapt to the way teams already work, rather than forcing them to learn a new system. Using AI, builders can define sequencing preferences in plain language, and the system automatically generates an optimized build flow.

Instructions such as “assemble connectors with more than six wires first” or “place splices from largest to smallest” are interpreted directly and applied across the entire process. The result is a clear, logical sequence that reflects real-world manufacturing priorities. Instead of rigid rules or manual reordering, teams gain a flexible system that supports consistency while respecting individual workflows.

This approach allows AI to act as a practical assistant rather than an abstract layer of complexity. It simplifies planning, reduces setup time, and helps ensure every build follows a structure that makes sense on the factory floor.

A long-standing challenge in wire harness production is the disconnect between design and manufacturing. SmartBuild addresses this by generating build instructions directly from validated Arcadia design data. This ensures every station is working from the most current and accurate version of the harness.

There are no outdated drawings, manual updates, or uncertainty about revisions. When a design changes, the build instructions update automatically. Technicians simply approach a Digital Build Station, load the formboard at full scale, and begin assembly using reusable fixtures directly over the display.

For teams that continue to use traditional wooden or metal formboards, the Hybrid Build Station offers the same guided clarity without requiring changes to existing layouts. In both cases, smartBuild integrates smoothly into established processes rather than disrupting them.

Quality assurance is most effective when it happens at the right time. With smartBuild, continuity and isolation testing are built directly into the assembly workflow instead of being handled as a separate step.

Technicians receive immediate visual feedback when issues occur, allowing mis-pins or missing wires to be corrected during the assembly process. Even large, complex harnesses with thousands of test points can be validated directly at the build station. This workflow improvement reduces rework, eliminates unnecessary movement across the factory, and helps teams maintain consistent quality without slowing production.

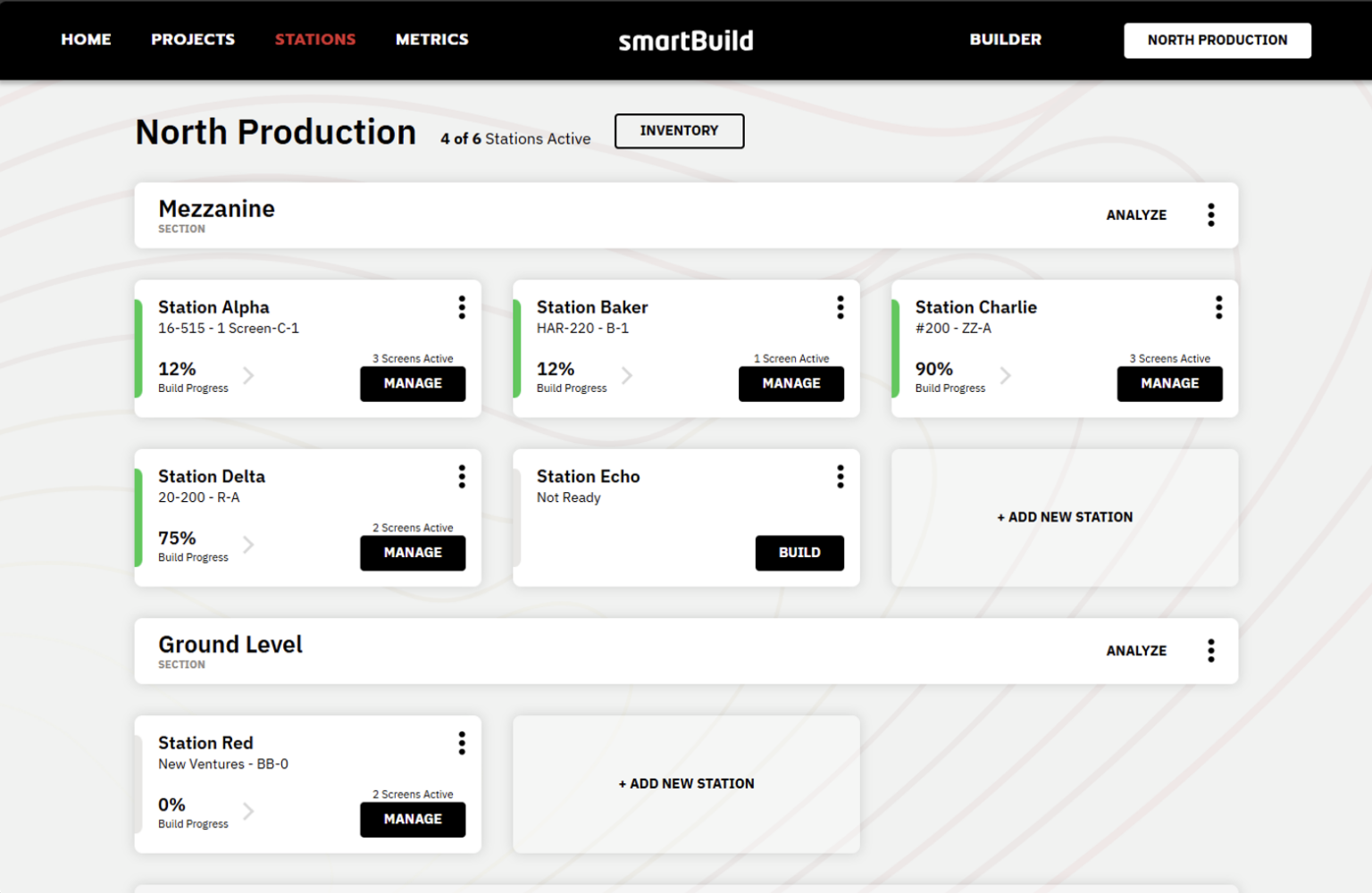

As operations grow, visibility becomes increasingly important. smartBuild captures every action, test result, revision, and performance metric in the cloud, creating a single, reliable source of truth across the organization.

Supervisors and leadership teams gain real-time insight into production status, throughput, and bottlenecks across stations and facilities. Decisions are based on accurate data rather than assumptions or informal knowledge, making it easier to identify improvements and scale efficiently.

When guided instructions, AI-driven sequencing, digital formboards, integrated testing, and real-time traceability come together, the result is a more scalable, predictable, and manageable manufacturing process. Uncertainty is reduced. Errors are caught earlier. Workflows become easier to follow and easier to improve.

smartBuild does more than increase speed or accuracy. It simplifies complexity and brings structure to every stage of wire harness production. This is modern wire harness manufacturing—designed to be practical, intelligent, and built for the people who use it.

Download our smartBuild eBook to learn more about how you can revolutionize wire harness design to manufacturing.

Chris Flaharty

Senior Account Executive, Re:Build Cadonix

chris.flaharty@cadonix.com