Member Company Feature

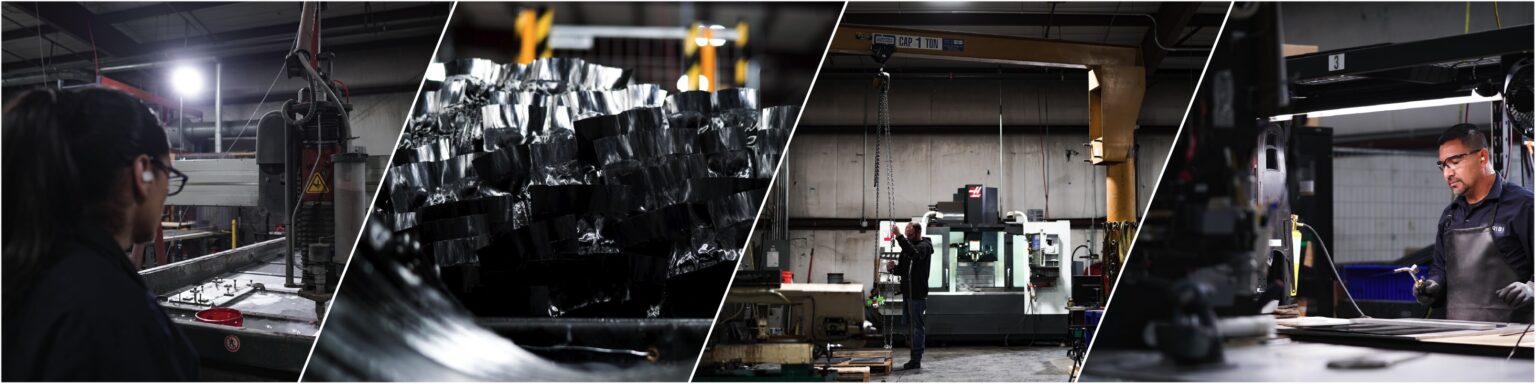

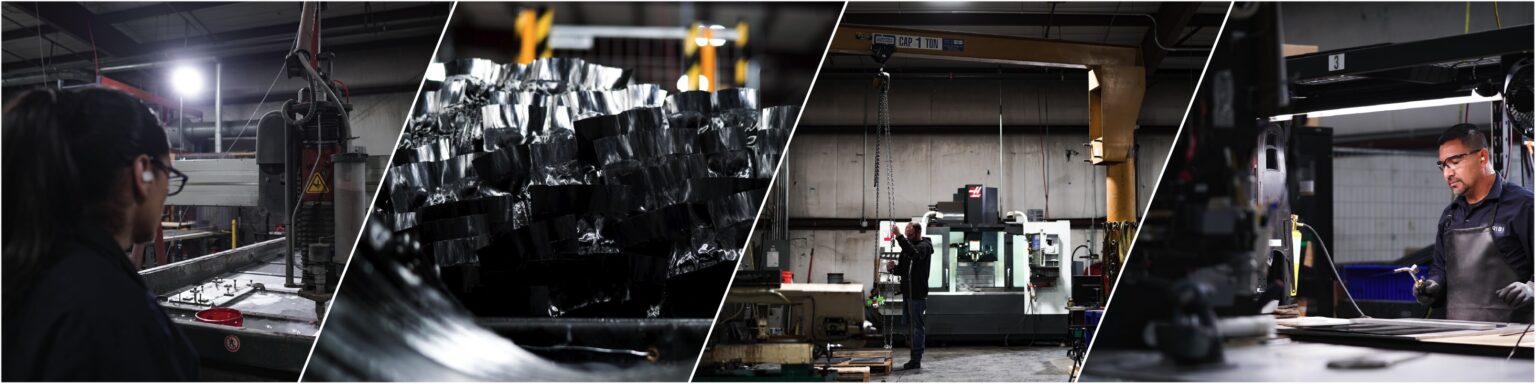

Oribi Manufacturing was founded in 2008 by Jack Wilfley with a bold vision: to redefine the composites industry through innovative automation for the production of continuous fiber-reinforced thermoplastics (CFRTP). What began as a small operation with just one layup machine quickly evolved into a pioneering force in the manufacturing of lightweight structural thermoplastic components for high volume applications.

From its base in Commerce City, Colorado, the team has spent more than 15 years perfecting the art and science of transforming advanced materials into high-performance components. While traditional composite manufacturing often relies on labor-intensive manual processes, the company took a different path, investing in automation and innovative forming techniques that make composite manufacturing faster, more affordable, and more accessible to a wider range of industries.

Historically, composite materials, particularly those with continuous fiber reinforcement, have been largely confined to niche applications in the aerospace industry. While these materials offer tremendous potential to reduce weight, improve performance, and reduce costs, they’ve lacked an affordable conversion technology to turn them into finished parts at scale.

This is where Re:Build Oribi comes in. By partnering with customers from the earliest stages of design, the team combines expertise in composite material part design with production optimization to enable cost-effective, high-volume manufacturing. Through a sophisticated five-step process, raw materials are transformed into high-performance composite parts that are stronger, lighter, and tougher than traditional alternatives.

These lightweight structural components serve demanding applications across multiple industries including Aerospace & Defense, Cleantech, Health, Industrial, and Mobility sectors. Re:Build Oribi maintains ISO 9001:2015 certification and is both Berry and ITAR compliant, meeting strict requirements for domestically sourced materials and controlled defense-related manufacturing. Their quality policy centers on delivering defect-free advanced composite products, 100% on time, with a relentless focus on continuous improvement.

Today, Re:Build Oribi stands at the forefront of a materials revolution. By unlocking the full potential of continuous fiber-reinforced thermoplastics through innovative automation and manufacturing expertise, they’re making advanced composite structures accessible to applications and industries that previously couldn’t justify the cost or lead time. As part of Re:Build Manufacturing’s network of advanced manufacturing capabilities, the company continues to invest in new technologies and processes that push the boundaries of what’s possible with thermoplastic composites. The mission remains clear: to deliver the promise of highly engineered composites at the speed, cost, and scale that modern manufacturing demands.

Courtney Wilson

General Manager

c.wilson@oribicomposites.com