Let’s take a look back at 2023 and the Re:Build team’s outstanding accomplishments.

Re:Build Optimation reached more than three years—equivalent to more than one million exposure hours—without a lost-time injury. Consequently, Re:Build Optimation’s Experience Modification Rate (EMR) has been reduced to just 0.66, while the average for the industry is 3.8. The entire team has demonstrated that they can work safely while providing their customers with superior design, engineering, fabrication, installation, and maintenance services. Their vigilance serves us well as we strive to mitigate future risks, with a goal of eliminating injuries at work. Small actions have made a difference and had positive outcomes. Our long-term strategic plan aims to continually improve environmental, safety, and health performance through leadership and employee engagement and the implementation of technically sound procedures and high-quality, skills-based training. We are extremely proud to have achieved this milestone.

The Re:Build CDI team focused on their Lean transformation journey in 2023. Ten senior leaders and fifty-one team members participated, running ten rapid improvement events in CDI’s aluminum sheet metal value stream. Each team accomplished breakthrough objectives, delivering results that improved operations. They chose “double the good” or “half the bad” metrics, which were stretch goals. Some of their accomplishments included:

When CDI began its transformation journey, the team was apprehensive, but decided to trust their coaches. One year into their lean journey the CDI team trusts the process. They noted they had been working on the same issues for years, but never with company alignment or support or a clear roadmap. Now they not only trust the process, but use it to run the business.

Lean thinking and practice sound simple—eliminate waste in any given process through continuous improvement while demonstrating respect for people. However, CDI found that while the concepts are easy to grasp, putting them into practice in a complex environment is difficult and requires commitment and a lot of effort. This is why CDI describes Lean as a time-based strategy. Change didn’t happen overnight. Improving things took time, hard work, and respect for people. CDI has changed its workplace culture so that everyone is now equipped with Lean tools and knowledge and is empowered to continuously improve the world around them and make great things happen.

In the spring, Re:Build launched a new corporate website that showcases the Re:Build family of companies. The structure of the site is an excellent example of the teamwork and collaboration we strive for at Re:Build. Teams from across the company worked countless hours to develop an engaging, user-friendly, informative site. It clearly conveys our mission to revitalize U.S. manufacturing, our expertise in operations management, product manufacturing, technical and engineering proficiency, and product lifecycle management, the wide range of our engineering and manufacturing capabilities, and the diverse industries we serve.

Re:Build DAPR launched the RBM600 Solar CZ Puller, designed for the manufacture of high-purity ingots used in the photovoltaic solar materials industry. This state-of-the-art equipment demonstrates Re:Build’s dedication to driving innovation, fostering U.S. manufacturing, and delivering products designed and built in this country that meet the highest standards of quality and performance. With innovation, safety, and expertise at the core of its design, the RBM600 marks a new era in solar crystal growth equipment and paves the way for a brighter, more sustainable future.

Now located in Wilmington, Massachusetts, Re:Build Fikst operations occupies a significantly larger, upgraded facility. With this new space comes a wealth of opportunity and advanced equipment. This change is enabling Re:Build to assist clients more effectively and efficiently than ever before.

Re:Build Oribi Composites launched a new line of continuous fiber reinforced thermoplastic tubes and profiles. The significant benefits of this product line stem from our highly automated processes. The components meet stringent performance requirements at a lower price when compared to thermoset materials. In addition, our use of proprietary layup and modeling software enables Re:Build’s engineers to optimize the composite layups virtually and validate manufacturability of complex parts with less iteration, at a lower total cost.

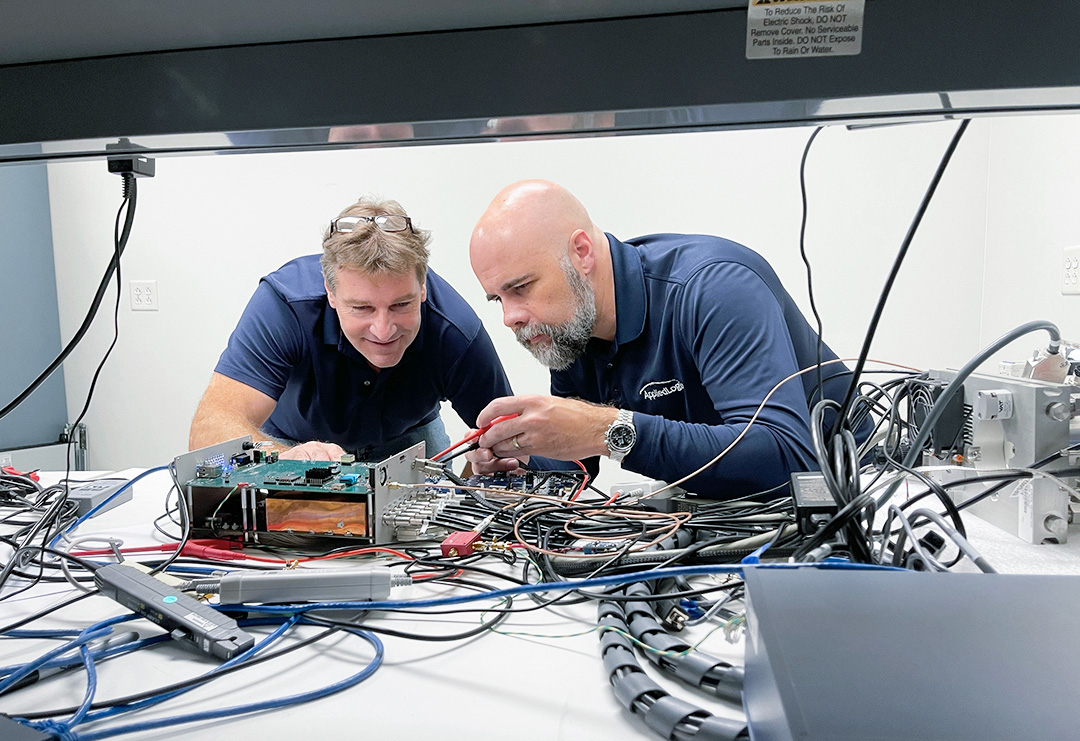

Re:Build AppliedLogix has supported a forklift and pallet truck manufacturer in their transition from lead-acid to smart lithium batteries since 2018. In 2021, AppliedLogix partnered with an alternative-energy consultant to design from the ground up a lithium ion phosphate battery pack for high-throughput, three-shift operations.

Our customer tasked AppliedLogix with system engineering, functional safety, power path design, battery management system integration, all smart-battery features (for example, truck and charger communication, Human Machine Interface (HMI), data logging, and telematics), handling and assembly tooling, validation, and agency testing support.

In November, the AppliedLogix team entered their battery prototypes into an on-truck qualification and reliability testing phase. The team’s extensive knowledge of the language of a smart battery and their expertise in designing the “smart” portion enabled it to achieve a first-ever, “first-key-on” success for the customer. The battery and the electric equipment communicated to each other on the first try via a digital link. In the past, other battery manufacturers spent weeks, sometimes months, testing and troubleshooting the customer’s smart battery. This success was made possible by the expertise of the entire AppliedLogix team.

Our most important achievement in 2023 was breaking ground for our first regional manufacturing site, located in the New Kensington Advanced Manufacturing Park in Pennsylvania. The strategically located 175,000 square foot site was in disrepair (it was once one of Alcoa’s production and research facilities) and received an injection of $81 million for renovations and operations, $31 million from the state and $50 million from Re:Build. Operations will focus on state-of-the-art fabrication, manufacturing, and integration and assembly projects in high-growth, innovation-driven industries, including energy, life sciences, robotics, electric mobility, satellite communications, and aerospace. This endeavor is a true public-private partnership and Re:Build anticipates it will create 300 jobs within the next three years. Renovations are well underway, so stay tuned for additional updates.