Buying American – What It Means

At Re:Build Manufacturing, we are focused on building the next incarnation of the great American industrial conglomerate. As GE, RCA, DuPont, etc. created a great economic engine 100 years ago, we want to be part of a revitalization of that engine of progress and economic opportunity – the manufacturing economy – today. As such, we are working on the supply side, creating the ability, the means, to produce complex industrial products in America. But part of what ails us today is the demand side; the flood of imports that we consume as businesses and individuals. In 2023 alone the United States imported almost 4 trillion dollars’ worth of goods and services. That’s a hard figure to conceptualize, so to put it into context, that’s ~22x Elon Musk’s total net worth of $186 billion. That didn’t make it any more relatable, did it? Put another way, it’s 66.7 million times the average U.S. salary.

August New Hires

Welcome to our new hires that joined Re:Build Manufacturing in August! Their diverse skills are sure to spark innovation and drive us forward. We are excited to see the fresh perspectives and contributions they will bring to the team!

Breaking Barriers: Elevating Women in Production Roles

As a corporate member of Women in Manufacturing (WiM), Re:Build Manufacturing is excited to announce that two of our employees have graduated from the Empowering Women in Production program. Congratulations to Bernadette Sandoval, Production Lead at Re:Build Oribi Composites, and Raquel Rivera, Assistant Account Manager at Re:Build Cutting Dynamics, for their outstanding achievement!

July New Hires

We’re thrilled to introduce the newest members of our Re:Build Manufacturing family who joined us in July. We’re excited to have them on board and can’t wait to see the innovative ideas and positive impact they will create!

Re:Build Manufacturing Becomes a Megawatt Partner of Greentown Labs

Re:Build Manufacturing is now a Megawatt Partner of Greentown Labs, the largest climatetech startup incubator in North America.

June New Hires

Please join us in welcoming our talented new hires from the month of June! We look forward to the unique skills and fresh perspectives that each of them will bring to our team. Here’s to a bright future together!

May New Hires

We are excited to introduce the new Re:Builders who joined our team in May! It is wonderful to welcome so many new faces to the growing Re:Build family. We can’t wait to see what you all accomplish!

April New Hires

We are excited to introduce the new Re:Builders who joined our team in April! It is wonderful to welcome so many new faces to the growing Re:Build family. We can’t wait to see what you all accomplish!

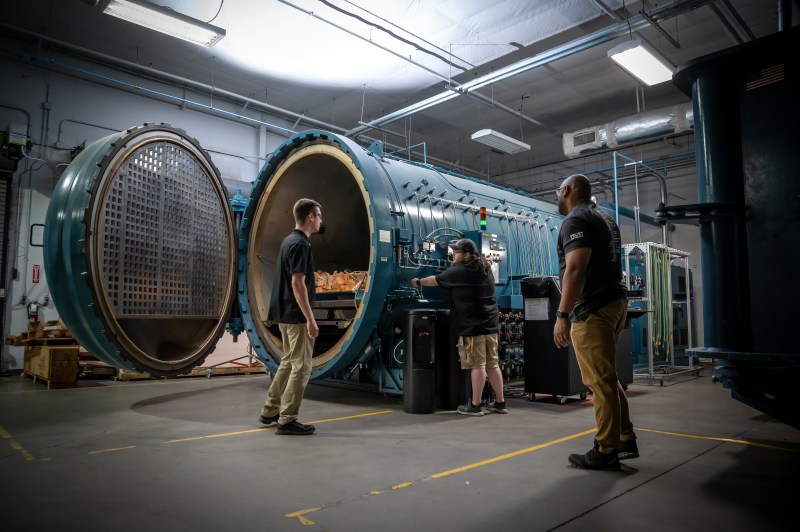

One Year of Re:Build New Kensington

We have very exciting news—Re:Build has officially begun operations at our flagship, large-scale manufacturing site in New Kensington, Pennsylvania! It was exactly a year ago when we announced this project to renovate 175,000 square feet of a legacy Alcoa facility that dates back to 1891! The complexity and number of challenges overcome to turn on the lights and get to work were mind-boggling.

March New Hires

Welcome to the new Re:Builders who came on board in March! We are excited to have so many wonderful, talented individuals join our growing Re:Build family.